Many studies on the theory of construction of machine tools, performed either at universities or in production companies, deal with specific technical parameters of the designed machine tools and try to assessthe direction of further development. Those involved can erroneously assume that this is the main attribute of the marketability of a machine tool. Who determines the marketability of machine tools ? The designers of companies or development departments or perhaps makteting departments?

Who determines the marketability of a machine tool? The answer is unambiguous. The customer and his requirement for what is necessary for him. He is the one for whom the machine tool supplied in future has a value – so-called customer value. of For marketing departments it is an art to find and predict the future customer value. Development institutes, universities and centres of competence (further -cooperating institutes) can purposefully complete manufacturing companies from the field of machine tools in a way, which would make the predicted customer value fully acceptable to the customer. Cooperating institutes, however, can never be those who will assess the orientation of the development in applied research. This is based on an idea that even the best machine tool with excellent technical and utility parameters is no good if it does not meet the requirements of the customer and is not marketable. From the fundamentals of the activity of cooperating institutes it cannot be expected that they themselves will offer the customer what they developed for commercial application. For this purpose they must have a reliable industrial partner and he must have a customer for whom he creates a value. In the opposite case all can be considered as only theoretical considerations, and this has nothing in common with applied research and development. Customer value Entrepreneurial success can be considered as the ability to predict the requirements of a customer and simultaneously to find ways how to create added values for customers either by themselves or with the help of cooperating institutes and companies. The customer anylyzes whether his requirements were fulfilled, if his needs were satisfied. The customer value is compared together with the utility values of the machine tool. Among utility values evalutaed by the customer can be:

• reliability of the function and operation of the machine;

• machining accuracy;

• multifunctionality;

• quality of the machined surface;

• product economy;

• environmental friendliness of operation;

• intelligence installed in the machine;

• labour productivity and effectiveness;

• automation of machine run.

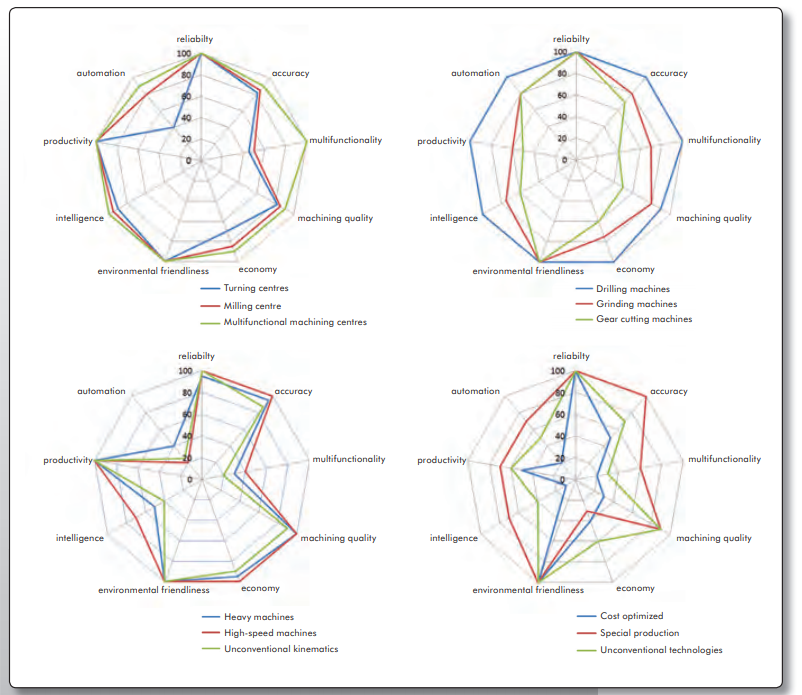

Fig. 8.1.1: Example of customers´ view on the utility properties of machine tools

The reliability of the function and operation of all machines is required without exception on the highest possible level. No customer wishes to repair his machine too often or have it set away. Machining accuracy is a criterion which reflects the quality of the design and type of the machine, activity of the operator,applied cutting operation and method of measurement of the final product. Highest requirements are traditionally laid on grinding machines, drilling machines and at present also on machining and multifunctional centres. Multifunctionality is the domain of the present time and does not only mean machining with more applied technologies. This means, as it has been stated above, converging of the values of the installed outputs of two basic machining operations, turning and milling. Surface quality in machining is in close relation with the achieved accuracy. These two attributes are usually closely related. The surface quality of components for aerospace industry is assessed differently from those for general industry. There is a boundary which cannot be exceeded by changing machining conditions since the design of the machine and the kinematic chain are absolutely inappropriate for the required surface quality. All customers will strictly consider the economy of operation. And it is quite obvious why. Ineconomic operation, based on e.g. an unnecessarily high installed output, decreases profitabilty and increases costs. Environmental friendliness is closely related with pollution of the environment of the machine tool. And this must not be confined only to the close neighbourhood of the machine. This can be a case of the protection of the operating staff against products created by the interaction between the cutting edge of the tool, the machined product and the process liquid. Intelligent systems of machine tools help the operating staff and techologists in the operating process to identify possible collisions and to specify optimum operating conditions of the machine tool. In addition they can make dealing with failures easier to the operating staff and service personnel of the manufacturing company.

The productivity achieved in installed machine tools is a combination of the following factors:

• mechanical properties of the machine tool;

• applied strategy of individual cutting

operations;

• experience and accuracy of the operating staff.

The bad mechanical design of a machine

tool cannot be compensated by good

electronics. The potential use decreases of

high-quality tools and consequently of the

productivity of machining. Automation,

namely of auxiliary functions, such as

automatic exchange of tools and of the

workpiece, plays a significant role in the

entire process in the assessment of the

customer value. Automation minimizes

the idle time and leads to an increase

of productivity. The above attributes are

sometimes considered by the customer

as utility properties of the machine tool.

Obviously different customers have

different views on the utility properties of

the purchased machine tools. This is why

the outlined and discussed properties of

machine tools have to be considered only

as an example. Fig. 8.1.1 gives the utility

properties of machine tools in percent for

various types of machine tools.

Added utility value of manufacturer

Besides monitoring amd searching for the

utility value for a customer, the manufacturer

can offer services which make the offered

machine tool more attractive. The machine tool itself does not mean anything to most

customers. The customer needs to deal with

the task of machining of the given component,

to obtain the machine tool as soon as possible

and if possible for an acceptable price.

The added utility of the manufacturer comprises:

• funding of the purchase of the machine tool;

• supply of the adjusted machine tool;

• above standard service;

• rapid supply;

• preferential training of the operating staff;

• testing of the customer´s workpieces prior

to the purchase;

• participation in the development of

the purchased machine tool;

• cooperative activities.

Funding is carried out in a way that the customer, namely in case of complete industrial plants, obtains a special schedule of instalments or a bank credit can be arranged for him. The supply of [bare[ machine tools with unadjusted technologies for the customers´ workpieces is slowly becoming history. The customer wants to be sure that his components can be machined on the purchased machine tool. Manufacturers create technological studies demonstrating the machining of the component, which they add to their offer.